Product Detail

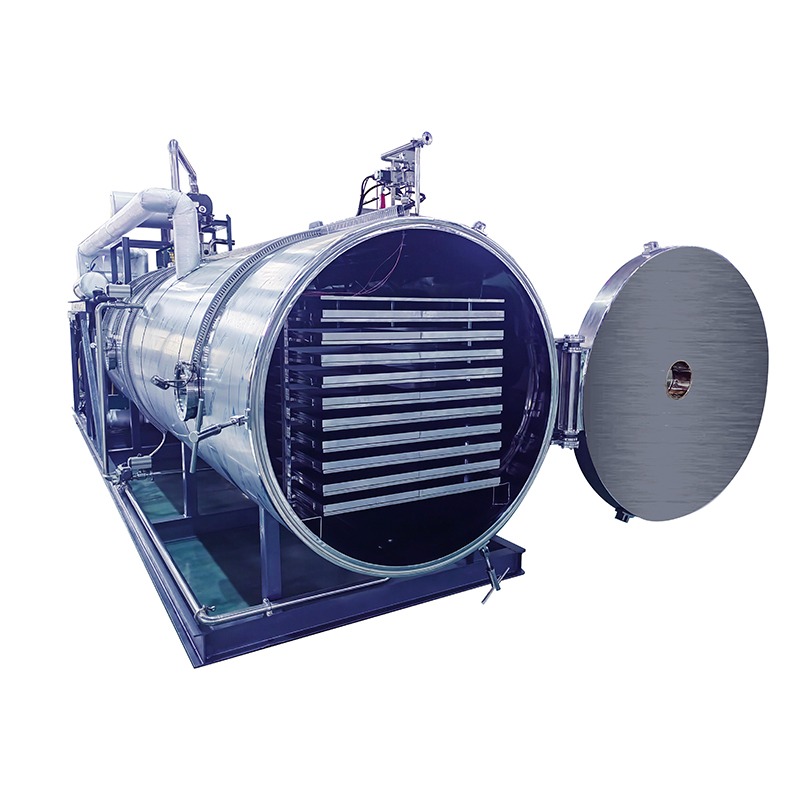

200Kg Food Industrial Freeze Dryer / Lyophilizer NovaDryer-FD200

Detail

200Kg Food Industrial Freeze Dryer / Lyophilizer NovaDryer-FD200

Main Features:

SUS304 stainless steel chamber, cold trap,shelves and trays

Back cold trap is integrated with front chamber.

R507 refrigerant

Silicone oil for shelf heating and cooling

Oil rotary vacuum pump

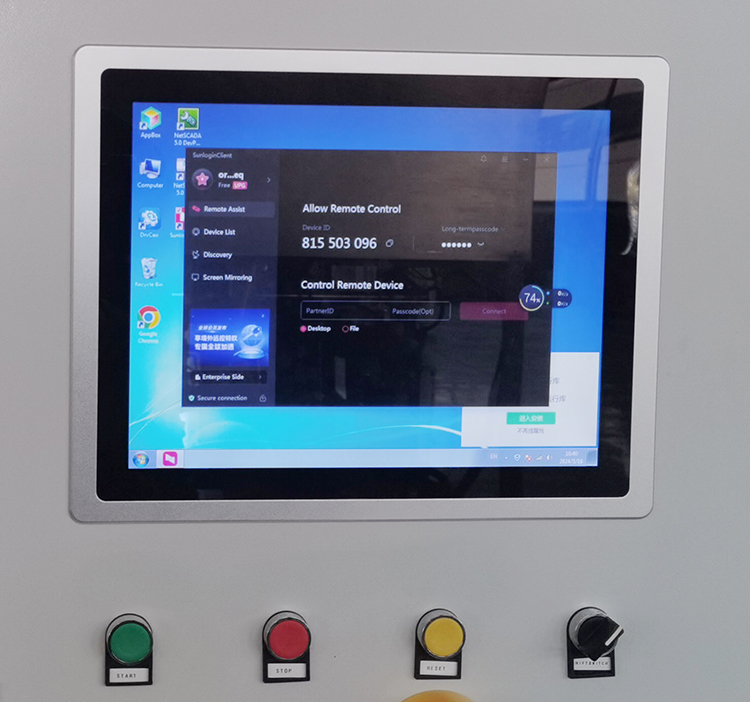

Omron PLC controller with touch screen

Netscada Real-time Monitoring Management

Wifi and remote control for trouble shooting

IPC based on Windows system

Automatic and manual dual control modes

User programmable for recipe management

Logging administration

Three-level user rights management

Specifications

| General Information | ||||

| Model | NovaDryer-FD200 | |||

| Load Capacity(approx.) | 200Kg | |||

| Maximum ice capacity | 300kg | |||

| Control | Microprocessor | |||

| Dimensions (Lx W x H,mm) | 7600×2100×3400 | |||

| Weight (approx.) | 7,500kg | |||

| Chamber | ||||

| Chamber type | Cylindrical(drum) | |||

| Maximum design pressure | Normal pressure | |||

| Maximum design temperature | Room temperature | |||

| Finish | Ra≤0.5um (0.5Mircon) | |||

| Validation port | Included (1, on the top of chamber) | |||

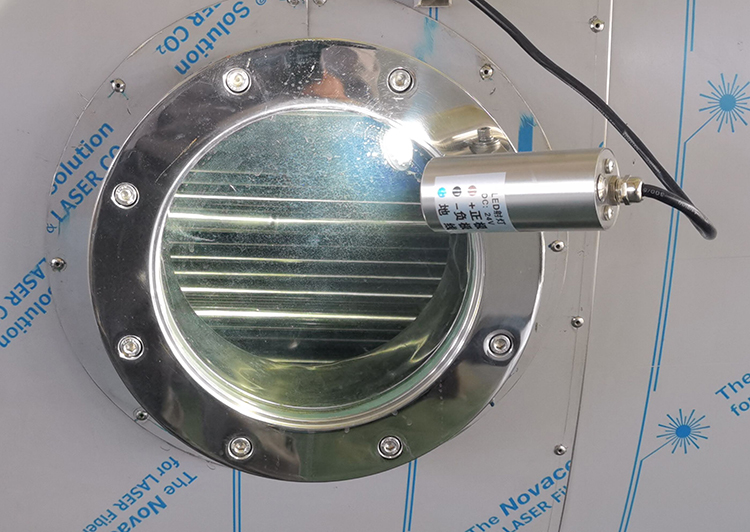

| Viewing port | Yes, with LED illumination | |||

| Qty. | 1 | |||

| Location | Side | |||

| Dimensions | DN200 (mm) | |||

| Material | ||||

| Internal | SUS 304 | |||

| Insulation | Polyisocyanurate foam | |||

| External cover | SUS 304 | |||

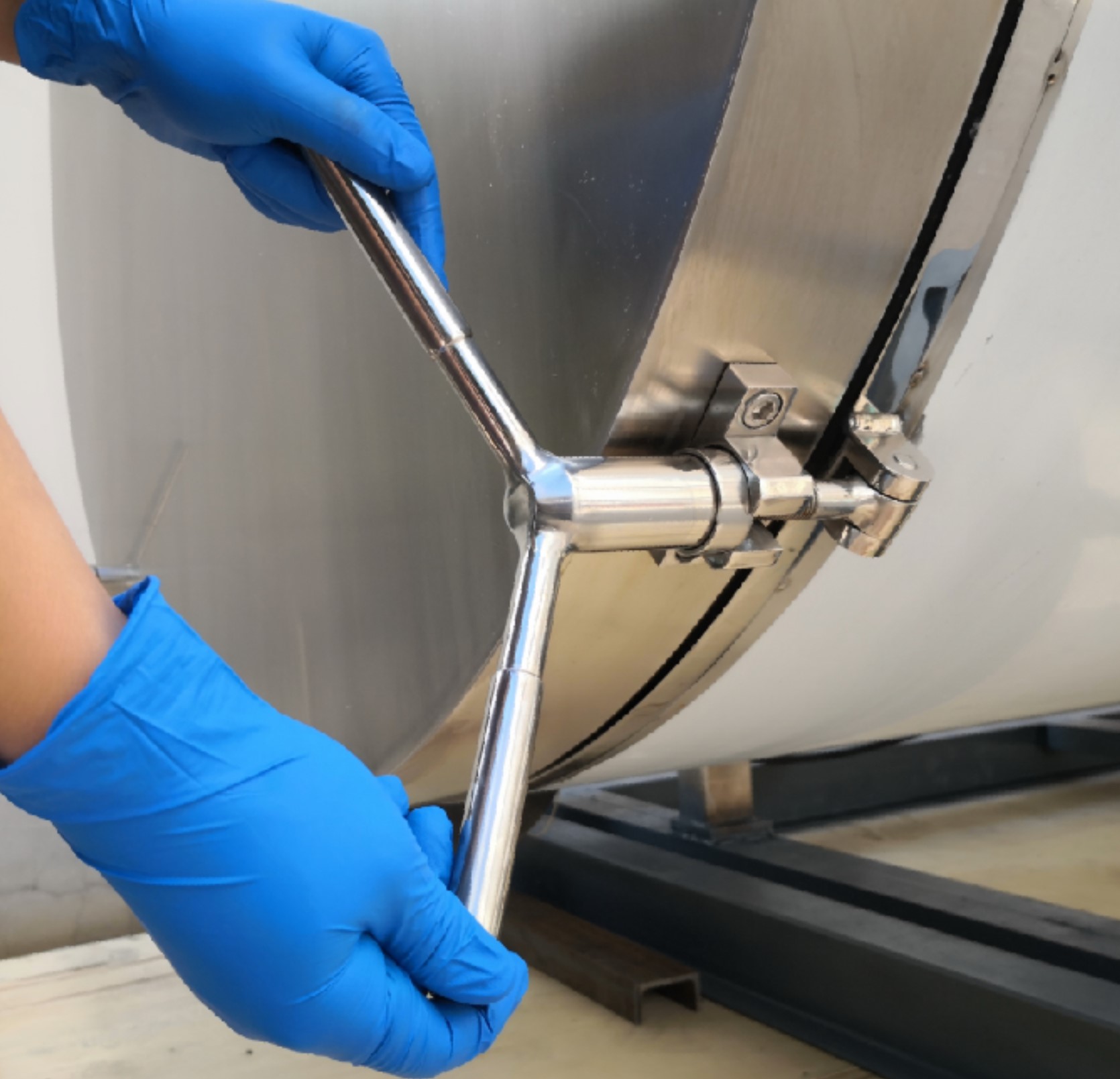

| Door | ||||

| Finish | Ra≤0.5um (0.5Mircon) | |||

| Viewing port | Included | |||

| Qty. | 1 | |||

| Location | On height 1.2m (approx.) | |||

| Open direction | Right (face to door, hinge on right side) | |||

| Open angle | More than 110° | |||

| Gasket | O-shaped silicone rubber single gasket | |||

| Locking arrangement | Auxiliary manual handle | |||

| Material | ||||

| Internal | SUS 304 | |||

| Insulation | Polyisocyanurate foam | |||

| External cover | SUS 304 | |||

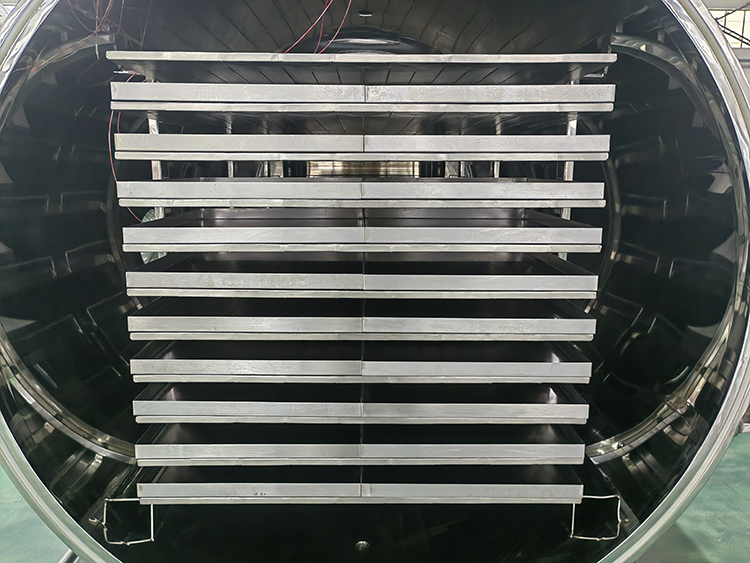

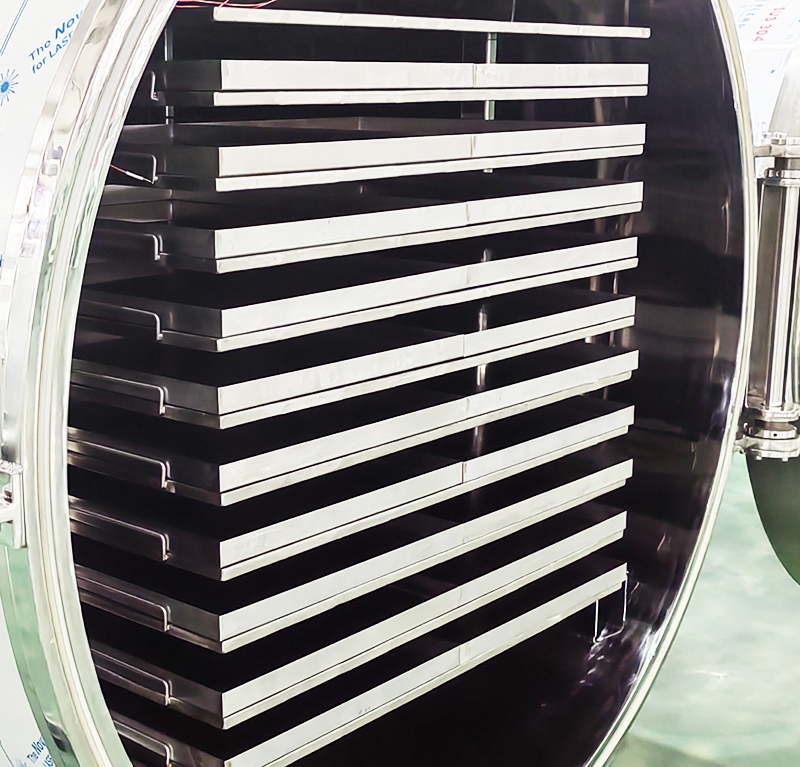

| Shelves | ||||

| Temperature range | -45°C to + 80°C | |||

| Shelf temp. sensors (shelves) | 3 (Silicone oil inlet and outlet) | |||

| Sensors | 3 | |||

| Qty. of shelves | 10+ 1 (upper radiant shelf) | |||

| Dimensions (LxWxT,mm) | 2200 x900x15 | |||

| Shelf area (M2) | 19.8 | |||

| Shelf space(mm) | 70 | |||

| Tray size(mm) | 547x445x30 | |||

| Tray Number(PCS) | 80 | |||

| Hose of flexible connection | Welding | |||

| Finish | Ra≤0.5um (0.5Micron) | |||

| Level | ≤±0.5mm/m | |||

| Material | SUS 304 | |||

| Condenser | ||||

| Condenser type | Cylindrical | |||

| Viewing port | Illuminated | |||

| Qty. | 1 | |||

| Location | Easily observe the whole inside condenser | |||

| Dimensions | DN200 (mm) | |||

| Final temperature | -65℃ | |||

| Cooling time (+20 to -40°C) | ≤30 minutes (empty) | |||

| Maximum design pressure | Normal pressure | |||

| Maximum design temperature | Room temperature | |||

| Finish | a≤0.5um (0.5Mircon) | |||

| Coiled pipe material | SUS 304 | |||

| Internal | SUS 304 | |||

| Insulation | Polyisocyanurate foam | |||

| External cover | SUS 304 | |||

| Shelf Heating /Cooling | ||||

| Circulation pump | ||||

| Brand | DF | |||

| Model | CDL32-1 | |||

| Type | Centrifugal pump | |||

| Qty. | 1 | |||

| Motor power | 2.2kW | |||

| Shelf heat exchanger | ||||

| Brand | Catro | |||

| Type | Sealed brazed stainless steel | |||

| Qty. | 1 | |||

| Heater | PID control | |||

| Maximum heating power | 24KW | |||

| Thermal fluid | Special heat conducting oil for freeze dryer | |||

| Shelf cooling time (+20°C to -40°C) | ≤60 minutes (empty) | |||

| Heating rate | 1℃/min (approx.) | |||

| Refrigerating System | ||||

| Compressor | ||||

| Brand | Frascold | |||

| Model | 2Z40-123.62Y | |||

| Type | Two-stage low-temperature piston compressor | |||

| Qty. | 1 | |||

| Motor power | 29.5kW | |||

| Refrigerant | HFC-free R507 | |||

| Main refrigerating units | ||||

| Thermostatic expansion valve | Danfoss | |||

| Solenoid valve | Danfoss | |||

| Service valve | Castel | |||

| Safety valve | Castel | |||

| Capped valve | Castel | |||

| Sight glass | Danfoss | |||

| Water cooling condenser | JD | |||

| Oil separator | Emerson | |||

| Gas-liquid separator | Fasike | |||

| Filter | Filter case: Fasike Filter core: Fasike | |||

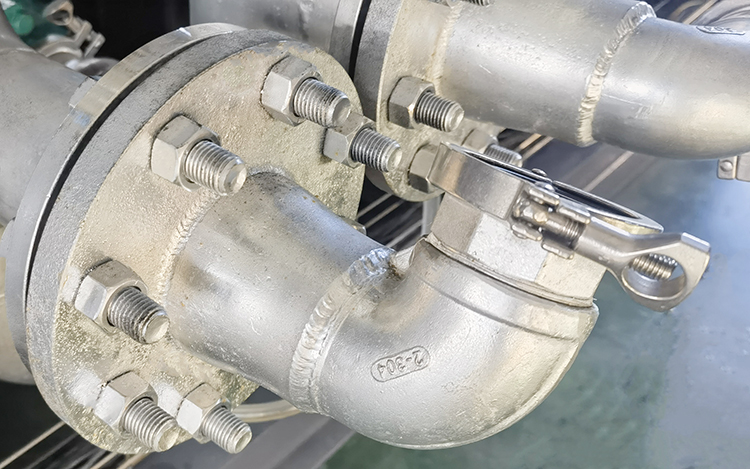

| Vacuum System | ||||

| Final vacuum | ≤2.7×10 -2mbar | |||

| Evacuation time | ≤30minutes (1×103 mbar to 1×10-1 mbar) | |||

| Vacuum pump | ||||

| Brand | Baosi | |||

| Model | DRV175 | |||

| Type | Oil rotary | |||

| Qty. | 1 | |||

| Flowrate | 175m3/hr | |||

| Motor power | 5.5Kw | |||

| Anti-suction valve | Included | |||

| De-icing | ||||

| Hot Water or Steam Inlet/Outlet Valves | ||||

| Brand | Lyofenik | |||

| Type | Pneumatic butterfly valve | |||

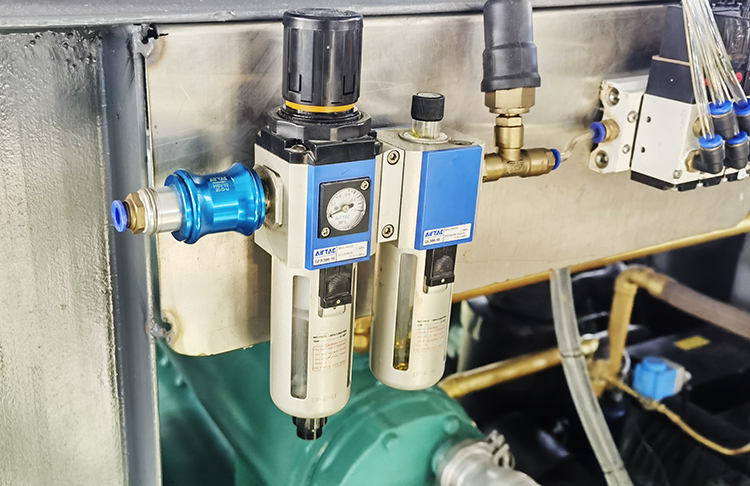

| Pneumatic System | ||||

| Gas source disposal unit | AIRTEC | |||

| Air pressure switch | EUROSWITCH | |||

| Pneumatic Valve | Lyofenik | |||

| Control System | ||||

| Software | FD-5000 | |||

| Automatic | Included | |||

| Manual | Included | |||

| PLC+PC (User programmable) | Omron(with Wifi remote control) | |||

| Industrial personal Computer | IPC | |||

| Vacuum gauge | POSIFA | |||

| Temperature probe | PT100 | |||

| Breaker | Schneider | |||

| Contactor | Schneider | |||

| Relay | Schneider | |||

| Safety System | ||||

| Vacuum failure protection | Included | |||

| Temperature failure protection | Included | |||

| Compressor protection | Included | |||

| Other motors protection | Included | |||

| Interlock protection | Included | |||

| Utility Requirement (Approx.) | ||||

| Electricity - total electrical load | 62kW (380V/50Hz,3 Phase/5 Wires),125A | |||

| Power Consumption | 44kW(Approx.) | |||

| Cooling water for refrigerant cooling | 25m3/hr (1.5≤P≤2 Bar, T≤28°C) | |||

| Cooling water pipe diameter (DN) | 50 | |||

| Defrosting water | 2.5T/Batch (P≥3 Bar, T=80℃) | |||

| Compressed air for pneumatic valves | 60L/min(4≤P≤8 Bar) | |||

Product details